Bioplex News for 2025

Season's Greetings

A Life Cycle Assessment of the hybrid digester, built in 2018, was undertaken. This assessment shows that our pioneer hybrid digester (except electrical items) has at least twenty years to go before any major renovation is needed.

Fermen8® can be supplied as a "standard" peat-free compost or with earthworms and their casts, the latter is valued at over £1,000 per tonne.

Some of the farm-produced biogas is separated, the methane is compressed and stored on site as compressed natural gas (CNG).

Renewable energy as Bio-CNG production is at least carbon zero when produced on a farm or within green community. Each red gas-cylinder can hold 125 kWh total energy.

See www.en-gas.com

Bioplex News for 2024

Autumn Clean Out

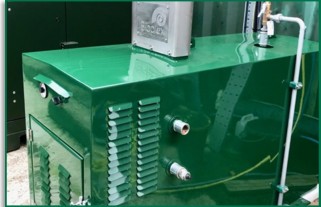

During this autumnís clean out of the pre-digester vessel, two things were noted.

Firstly, the heat exchanger pipework is clear of any crystalline coating.

Conventional digesters often suffer from a coating of minerals, including struvite, on surfaces such as heat exchangers. This forms a layer of insulation, reducing heat transfer. A build-up of crystals can cause blockages, within pipes between vessels and pumps.

The Bioplex Process heat exchange pipes (with some digested straw on them), as seen in the photograph, were fitted over 15 years ago. No sign of any crystal deposits growing on them, nor any drop in heat exchange efficiency. The steel pipes remain grey in colour, almost like the day they were installed!

Secondly, the gritty inorganic deposits, physically similar to soft wet sand and fine shingle, are easily and safely removed, whilst the rest of the digester plant continues to work. This "grit" is popular with the local gardeners!

A Livestock Farm with Minimal or No Ammonia Emissions?

Recent results show that treating farm animal slurry quickly with a hybrid digester can reduce atmospheric ammonia to very low levels. In addition the digestate has negligible ammonia emissions, so no need to cover storage tanks and lagoons?

| Windover Dairy, Longstock, Hampshire | ||||||

|---|---|---|---|---|---|---|

| Reception Tank Slurry | Reception tank FYM | Hydrolysis (2nd stage) screened fibre |

Methane (3rd stage) digester |

|||

| Dry matter | 10.50 | 16.20 | 18.50 | 2.04 | % | |

| Ammoniacal N (See Note 1.) |

751.00 | 1070.00 | 333.00 | 632.00 | mg/l | |

| Total Nitrogen | 2.66 | 2.70 | 1.57 | 2.59 | % | |

| Fresh Feedstock Farm Yard Manure (FYM) | Inside Reception tank during adding of feedstock FYM and mixing | Inside Reception Tank 10 minutes of after mixing | Inside Reception Tank 1 hour after mixing | Screened fibre to be stored and spread onto farmland | ||

| Ammonia (See Note 2.) |

93.7 | 2.2 | 0 | 0 | 0 | ppm |

| Notes: |

|

|||||

|

||||||

The Ammonia captured by the patented process and converted into a stable slow release fertiliser results in less dependence on chemical fertilisers. And no odours around the farm.

Off-Grid Energy Use and Storage

The farm digester site is off grid, due to high expense of connecting to the grid and purchasing a compatible biogas fuelled generator.

We are currently evaluating other viable uses of biogas.

One such use is to dissociate (or upgrade) biogas into methane as compressed natural gas (CNG) and carbon dioxide at a small scale. Alas much of the equipment currently available is for the much larger digesters.

We now host a biogas to bioCNG upgrader which has been designed for smaller (mini or micro) digester sites. It uniquely uses a low cost process with no membrane or chemical consumables. The process only uses small amounts of water and electricity from the digester.

Each of the red gas cylinders in the photograph can store, in a relatively small space, energy up to 50kWh electricity and 150 kWh heat when used in a generator with heat recovery or 160 kWh heat from a gas boiler. The gas storage cylinders can last in serviceable condition for decades and the storage is constant - no reduction over so many cycles.

CNG can be used in vehicles, central heating boilers, cookers and generators.

Carbon Dioxide is used to enhance plant growth in greenhouses etc.

The energy from the farm hybrid digester is zero carbon - see Carbon Capture.

The Original Portagesters to Return?

The Portagester® was the earlier result of R&D by Bioplex Ltd and Universities to create a system where food and other organic wastes are loaded into a process vessel, treated to Animal By-Products Regulations and emptied onto a suitable composter.

The process vessel remains sealed throughout the waste treatment processing and transport from the waste source to the composting facility.

Adding Value to Hybrid Digester End Products

One example is cut flowers, locally grown in Fermen8®, the pasteurised and fermented screened fibre from the treatment of vegetation, horse stable and farm animal manure. This peat substitute compost, with its natural slow release fertiliser, is used exclusively on a recently established flower farm.

The flowers are grown organically, that is, with no herbicides, pesticides nor artificial fertilisers. And sustainably as all the compost and nutrients are home produced.

Fermen8® could be valued at £150 to £200 per tonne, maybe several times that with the addition of vermiculture resulting in earthworm casts. Plus thereís the extra value in the biogas and liquid digestate as a concentrated plant feed.

The next stage of the research is to convert any vehicles used on the flower farm to biogas or Bio-CNG or even home produced hydrogen - a future carbon audit should prove the enterprise is at least carbon zero to carbon capture.

Bioplex News for 2023

Good Results with Fermen8®

|

Freshly made pasteurised and aerobically fermented screened fibre "Fermen8®" in front. The older screened fibre behind: |

Thereís no scorching of the adjacent pasture grass, unlike the damage from raw untreated manure or slurry: |

|

|

|

In some cases the Fermen8® can have good population of naturally occurring earthworms: |

Trials of Fermen8® in commercial earthworm farming and the production of highly valuable worm casts used in horticulture: |

|

|

Colourful flowers grown in Fermen8® during 2023, including for church decoration and weddings:

UK Agriculture is reported to be a major source of ammonia polluting the air. This is the result of the release of ammonia from farm animal urine, horse stable and farm yard manure and the over use of chemical (non-organic) fertilisers such as those containing synthetic urea.

Ammonia, often combines with urban air pollution to form micro-particles which can cause respiratory health problems.

There is a potential solution which can result in cleaner air and less dependence on chemical fertilisers.

The results below are from air samples taken at an operating Farm250, showing ammonia emissions are controlled. Ammonia is captured by the patented process and converted into a stable slow release fertiliser.

When used on farmland, forestry, horticulture and gardens this results in little or no odour - lower or zero fertiliser costs - better plant growth - greater carbon capture.

| Fresh Feedstock Farm Yard Manure (FYM) |

Inside Reception Tank during adding of feedstock FYM and mixing | Inside Reception Tank 10 minutes after mixing |

Digested fibre and liquor. To be stored and spread onto farmland etc |

||

|---|---|---|---|---|---|

| Ammonia Day 1 | 37.4 | 3.7 | 0 | 0 | ppm |

| Ammonia Day 2 | 34.0 | 4.3 | 0 | 0 | ppm |

| Ammonia Day 3 | 35.2 | 3.9 | 0 | 0 | ppm |

| Ammonia NH3 gas measured by a BT-5800G Ammonia Gas Detector. Sampling within 0.5 metre of FYM, Reception Tank contents and screened fibre before handling, storage and spreading. | |||||

The pasteurised screened fibre (Fermen8®) is now part of a Lincoln University MSc study to see if it can replace peat as a growing medium. This is timely as there will be a ban on excavated peat within the next few years.

This University link was initiated by Barclays Eagle Labs. Other related Lincoln University dissertations include the study of ammonia through a farm with a hybrid digester, barriers to the use of anaerobic digestion in the UK and agricultural carbon balance.

A new Farm250 was installed earlier this year on a livestock and arable farm to treat its farm yard manure. The pasteurised and fermented screened fibre is used as a solid organic fertiliser on nearby arable land, some of it can be further processed into a peat-free compost with natural slow release fertiliser.

The biogas is from the digester is around 65% methane, the hydrogen sulphide is usually below 100ppm, so no gas scrubbing needed. Electricity generated is used on the farm with the surplus sold onto the grid.

Bioplex News for 2021

The Farm250 - is it an answer to agricultural ammonia problems?

Results of ammonia concentrations through the prototype Farm250:

| Sample | Feedstock | Reception Tank | Liquid Hydrolysate | Solid Hydrolysate | Third-Stage Liquor Digestate |

|---|---|---|---|---|---|

| October 2019 NH4N mg/l: | 1070 | 64 | 632 | ||

| May 2021 NH4N mg/l: | 1505 (1) | 751 (2) | 296 | 333 | 684 |

| Notes: | 1. Fresh farm yard manure. | ||||

| 2. Aeration of reception tank. | |||||

Do these preliminary results show that there could be an effective means of converting volatile ammonia into a stable fertiliser?

The Farm250 biogas plant with its patented hybrid (aerobic - anaerobic) process has operated reliably for two years. It has successfully treated cattle slurry, farm yard and horse stable manure, pasture toppings, spoilt hay and silage, vegetable garden and lawn mower cuttings etc.

There was a problem finding a suitable gas boiler. This has been resolved by using a top quality engineering and fabrication company with superb customer care:

See www.firsteng.com

(First Engineering Services Ltd)

The biogas, about 70% methane, has a gross energy value of 7.9 kW/m≥. The hydrogen sulphide is naturally under 150 ppm, so it can be used directly in most generators and boilers.

Farm250 R&D

A new bespoke outdoor biogas boiler to heat the digester and nearby buildings was recently delivered.

The novel Farm250 biogas plant has been designed, built and tested over the past two and a half years. Whilst the core biogas plant has operated reliably for about 18 months, the research and development continues with the add-on equipment and the outputs of biogas, fibre and liquor (digestate).

Biogas at 70 to 80% methane is used to fuel a 48v DC generator to charge electricity storage batteries. Both three phase and single phase electricity, via inverters, is used to provide power for the digester site and a nearby dairy farm. The next task is to investigate the separation of biogas in to methane, as compressed natural gas (CNG) and the residual carbon dioxide.

CNG can be transported in cylinders and used in converted road and farm vehicles and for use in engines, cookers, boilers and generators.

Fibre (Fermen8®) can replace peat as a growing medium, can be compressed into items such as flower pots and briquettes. The nutrient levels can be varied for the use of it, several new blends are to be made and evaluated.

The composition of the liquor or liquid digestate from a three-stage digester may differ from single-stage ones, especially the ammonia and sulphur levels. Investigations continue.

Back to TopThe first Farm250 biogas plant has completed over one year of continuous trouble-free running, fed on dairy cow slurry and farm yard manure in the winter months and pasture topped weeds when the cows are grazing nearby meadows.

The patented hybrid digester creates a steady supply of biogas, with an average methane level of 70% and Fermen8® which is currently in plant growing trials in numerous gardens, allotments and fields. It has been recently noted that Fermen8® also has good moisture retention.

Grit, a problem causing failure of conventional digesters within 4 to 7 years, is regularly and safely removed without interruption to the biological process.

The biogas can be used in equipment supplied by recommended companies; to produce heat, electricity and/or gases such as methane (CNG), carbon dioxide and hydrogen.

A biogas plant, using the patented Hybrid Digester, for farms with:

- 100 to 200 cow dairy herd, plus FYM, spoilt silage, pasture toppings, waste vegetation.

- Slurry only from up to 350 cattle.

- 250 to 400 sow piggery plus FYM, waste vegetation.

- 100 to 300 acres of crop and crop residues, cuttings.

A food waste version, to treat and recycle 5 to 10 tonnes per day whilst will enabling the operator to comply with ABPR Cat 3, will also be available.

To tailor the system to each site and to reduce costs, the customer has the option of adding their own choice of biogas CHP generator, boiler, additional gas storage, gas upgrading and materials handing.

For more information please go to www.jjcarter.com/anaerobic-digester

Fermen8® is produced during the process of the patented hybrid digestion. Current tests and plant germination and growth trials show this product could be as at least as valuable as the electricity from an AD plant.

Fermen8® is the fibre from the core of the digestion process, it is pasteurised (controlling pathogens, parasites and weed-seeds) and it contains natural slow release fertiliser whilst minimising ammonia emissions and water course pollution.

Back to TopAfter running on farm animal slurry this winter, the digester is now running on a mixture of farm yard manure, old silage and toppings.

The toppings are mainly nettles, thistles and ragwort which are left by the pasture fed cows, cut and collected for the digester. Pasture toppings can give comparable biogas yields to "energy crops", at a much lower cost.

A complete change of feedstock can be done in a single day, thanks to the hybrid process.

Studies and development work on a patented hybrid aerobic and anaerobic digester continue.

The aim is to enable family sized farms, communities, colleges etc to be self sufficient in renewable energy, fibre and natural fertiliser from a wider variety of feedstocks than used by conventional digesters. The whole system reduces ammonia emissions and enables carbon capture.

Back to TopBioplex Ltd and Aria Farming win the 2018 National Energy Efficiency Awards, RHI Project.

This follows on from the earlier award for the new hybrid aerobic and anaerobic digester, currently under test, to provide renewable energy and natural slow release fertiliser for a local dairy farm. This will enable it to be "off-grid", closed cycle in nutrients whilst carbon neutral.

Regional Energy Efficiency Awards

Bioplex Ltd and Aria Farming win the South East Region - Small Scale Project of the Year:

A new hybrid aerobic and anaerobic digester to treat slurry and farm yard manure plus weeds, old straw, spoilt silage, grass cuttings and waste vegetation on an organic family dairy farm.

It will provide electricity and heat for a dairy farm, enabling it to go "off-grid" and reducing the quantity of diesel fuel used in slurry spreading by having a much smaller amount of digested solids to spread. The natural fertiliser is stable, with a significant reduction in leaching to watercourses and airborne emissions.

The next stage is to bottle bio-methane (CNG) for use in heating, cooking and vehicles. Anaerobic digestion is complimentary to other renewable energy sources, such as wind, solar and micro-hydro.

The farm could meet all its energy needs, plus the surplus for the local community.

The patented three-stage digestion process naturally controls diseases, parasites and weed-seeds.

Re-Powering Your Digester

Many anaerobic digesters are temporarily shut down every 3 to 6 years so that inorganic sediments such as grit can be cleaned out. Normally this grit build up is hard to spot.

We can offer, through our partner companies, a longer term solution:

Back to TopThatís the average rate of deposition of grit and other inorganic materials we have found in conventional anaerobic digesters.

Each year, this means 10% less space in the vessel for digestion, the biogas yield falls and with automatic feeding there is an increased risk of over feeding and process failure. Other potential problems are blockages, poor mixing and less heat transfer.

The average lifetime of a conventional digester, before shut-down and digging out the grit is perhaps 4 to 6 years.

With our patented process, this problem can be significantly reduced, even eliminated.

Note: Images on the right show one yearís worth of sandy deposits from a conventional digester, which are almost impossible to remove by mixing and pumping.

Back to TopA new company to supply this small, yet important scale of anaerobic digesters will be announced later in 2015.

New Licensing in Progress

Licensing and technology exchange and licence for use of the Bioplex Process, in medium to large digesters, in countries bordering the Mediterranean Sea. Licence for Portugal starting in July 2015.

Biogas Efficiency

Several digesters using the Bioplex Process produce biogas with methane content in excess of 70%, thatís more energy from less gas.

Trials using solid fuel made from the screened and dried digested solids. There is little or no nutrients in the fuel, these nutrients can be spread onto fields and gardens in liquid or solid form as a natural slow release fertiliser.

Second Digester Passes 5-Year Milestone

A second food waste treatment plant, built in 2009, whose biogas (final stage) digester has not had problems with grit and debris build up problems that can occur with conventional AD plant.

Note that digester vessels are transportable, with pipes and electrical connections plugged in.

The reception and first stage digester under construction. The Bioplex process is used in this 125 kW AD plant and will use a mixture of farm animal and horse stable manures and home grown energy crops, under rotation.

Digester Passes 5-Year Milestone

A Bioplex AD plant which treats food waste in accordance with Animal By-Products Regulations has now been in successful use for 5 years. This digester vessel originated from an earlier trial on the same site and is still working well.

Bioplex News for 2013

Bioplex EU Expansion

Technology exchange and licence agreement for a manufacturing company to use the Bioplex Process in an EU country.

Kitchen Waste Portagester Operational

Second site using Portagesters to treat prison kitchen waste now operational. The food waste is digested, composted and screened - resulting in a good quality natural fertiliser and soil conditioner for on site use eg for gardens and within polytunnels.

The financial benefits are in the reduction or elimination of:

- waste disposal charges

- associated security with moving vehicles, bags and skips on and off site

- purchase of compost and fertiliser

Intangible benefits are:

- useful jobs and training within the institution

- control of pollution, odours, vermin and disease risk of food waste

- carbon sequestration and offset

Portagester on trial in the Channel Islands. Many islands around the UK have high waste disposal costs and may need to buy in compost/fertiliser for its farms/horticulture. The Bioplex Process is ideal for local recycling, energy recovery and job creation.

Many islands have their own diesel fuelled generators for electricity generation. These could be converted to combined heat and power, to exchange heat for biogas from a nearby digester. Surplus heat could be used for heating of buildings, greenhouses and amenities.

Fourth Plant to Gain ABPR Compliance

"Bioplex Process" source segregated food waste digester meets the Animal By-Products Regulations (ABPR).

This is the fourth Bioplex plant to comply. It fits neatly into an existing building, which has bunding and water catchment.

Back to TopLocal food waste treatment facility under construction, using the patented 3-stage anaerobic digestion and composting.

Summer '09

PG 1 digester at Center Parc. (Model shown includes additional on-board heater).

The trials showed that a small digester could convert kitchen/food waste within a small area on the site and produce a good fertiliser rich compost for the flower beds and lawns. The trailer can be towed around the resort to various restaurants, food shops and food waste collection bins. After digestion, the Portagester tips out the treated solids onto the composting pad and resumes the collection round. The complete cycle takes two to three days.

Spring '09

Chris Reynell helps to load a new PG 1 digester with manure at a livery stable. (Model shown includes additional on-board heater).

Roll on-off PG 4 Portagester® which can be moved and emptied using a standard hook load lorry. One PG 4 can treat 2,500 tonnes per year of food waste whilst producing a slow release natural fertiliser and biogas from the second-stage digester.

July - August '08

The Royal Welsh and Pembrokeshire Shows. The PG 3 Portagester® can treat up to 7 tonnes per batch every two days and is suitable for farm animal manure, grass and vegetable waste treatment.

May '08

PG 1 Portagester® and small second-stage digester delivered to South Dorset for trials on the treatment of organic wastes including household refuse.

March '08

HM Prisons digester building work complete. HRH The Princess Royal visits the site during the design and construction period.

February '08

PG 3 digester delivered to Westray, for use at an abattoir. Pictures show the digester dealing with boxes of spoilt vegetables.

Testing of one of the three PG 1 digesters built for HM Prisons kitchens.

June '07

Picture showing results of the "kitchen top" digester composting trials.

The digested kitchen waste is added to lawn mower clippings in a garden composter, which accelerates the process with less odours and more natural fertiliser as a result.

March '07

Start of the development of the "kitchen top" range of digesters. The aim is to provide digesters, small enough to be used at home and in the garden, to produce a nutrient rich natural fertiliser that will accelerate and improve green waste composting e.g. lawn mower clippings.

January '07

Otter Rotters produce a natural fertiliser rich compost for use in a nearby commercial nursery.

Although the kitchen waste should be meat excluded, due to the risk of meat in the collected material, the process has been designed to meet the DEFRA's Animal By-Products Regulations (ABPR) standards.

Back to TopTwo PG 2 digesters and biogas digester have been installed to treat kitchen waste from 500 homes.

January '06

The Longstock Portagester®; is run to produce natural fertiliser compost for selling to local growers. Farm animal and horse stable manure is pasteurised, digested and composted.

Bioplex News for 2005

October '05

The Portagester®; is an example of an anaerobic digester for DEFRA's Farming without Fossil Fuels project that looks at farming using home grown fuels and other renewable energy sources.

January '05

Project DIPROWASTE complete - results available to download.

Bioplex News for '04

October '04

Bioplex Ltd is to embark upon the evaluation of a patented low cost conversion of weeping walls, used widely on dairy farms, to an Anaerobic Digestion system. This will, in most cases, produce on-site energy and meet higher environmental standards.

September '04

Reading University Energy Group completes evaluation of a new farm waste treatment system, with production of fertiliser enriched fibre for composting and electricity.

August '04

WRc publishes landfill tax funded study of growing media derived from digested source separated household refuse, hotel, supermarket and catering wastes. Digested, composted and screened fibre makes a good nutrient rich and beneficial organic growing medium.

June '04

A new 5,000 tonne per annum farm and food waste digester, built under licence from Bioplex Ltd, operating in Co. Durham as a working prototype.

Mid point of EU funded (1.1 million Euro) digester research programme, DIPROWASTE (see www.diprowaste.com) to enhance the digestion process using novel techniques.

A result of EU collaboration is this German Portagester, built under licence.